Spacecraft Mechanisms Design Project

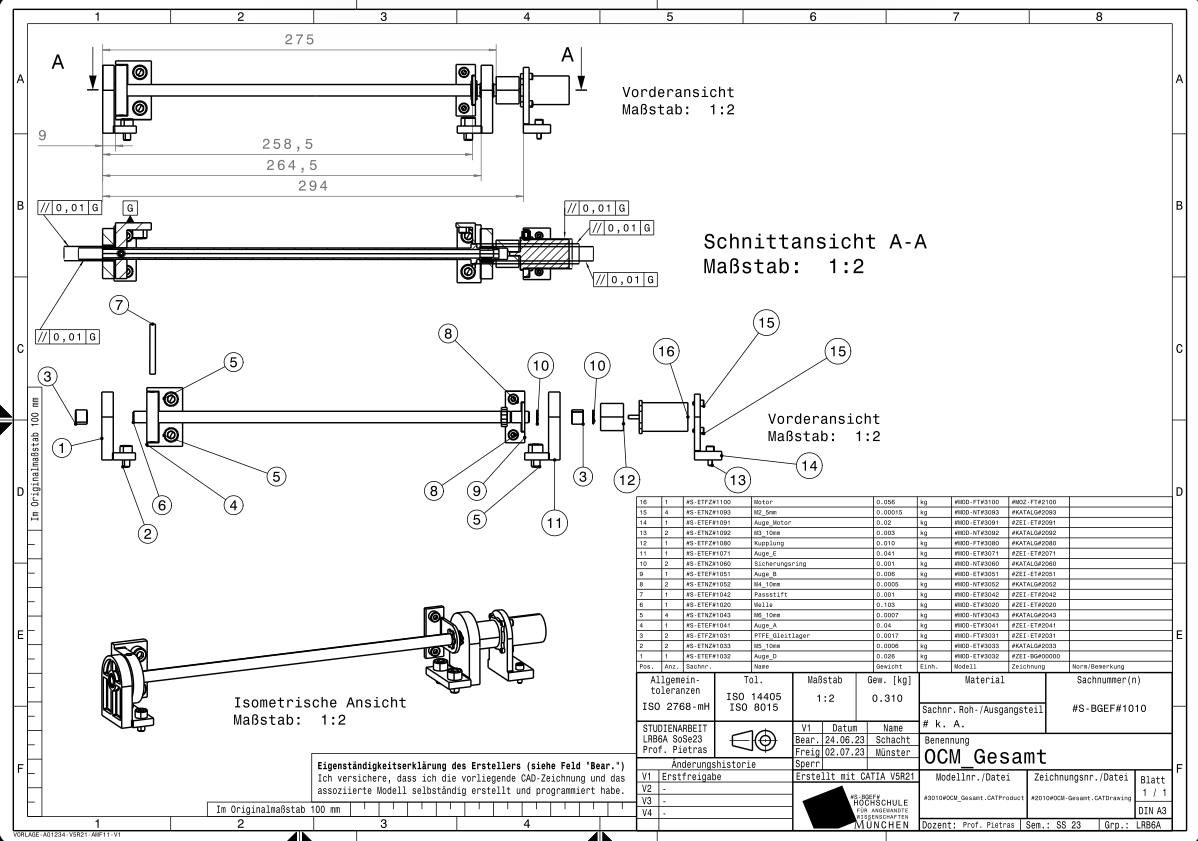

Aperture Cover Opening/Closing Mechanism & Launch Lock

Design, analysis, and verification of a motor-driven aperture cover mechanism and a pyrotechnic-free launch lock for the telescope of a scientific satellite, carried out in the “Raumfahrzeugentwurf (Konstruktion)” course at Hochschule München.

I. Introduction – Mission Objective & Social Value

Modern space telescopes provide critical data for climate monitoring, disaster response, and astronomy. To collect reliable measurements, the optics must arrive in orbit perfectly clean and must not be exposed to contamination or stray sunlight during launch.

Our project focused on the opening/closing mechanism (OCM) and the Launch-Lock Assembly (LLA) of the telescope’s aperture cover. Together, these subsystems keep the instrument safely closed under launch loads up to ±3.8 kN, and then open it on command once in orbit.

The design therefore needed to:

- Survive launch loads and vibrations while keeping the cover firmly locked.

- Open from 0° to 140° and close again within 30 s, without releasing any debris.

- Meet ECSS structural safety factors and lifetime requirements for repeated ground tests and in-orbit operations.

II. Design & Methods – Mechanism Architecture

1. Opening/Closing Mechanism (OCM)

The OCM rotates the aperture cover about a fixed hinge. A high-reliability phySPACE 19-2 hybrid stepper motor drives a lightweight Ti-6Al-4V hollow shaft via a flexible coupling. The shaft is supported by four PTFE plain bearings arranged as two fixed and two floating supports, which carry launch loads and accommodate thermal expansion.

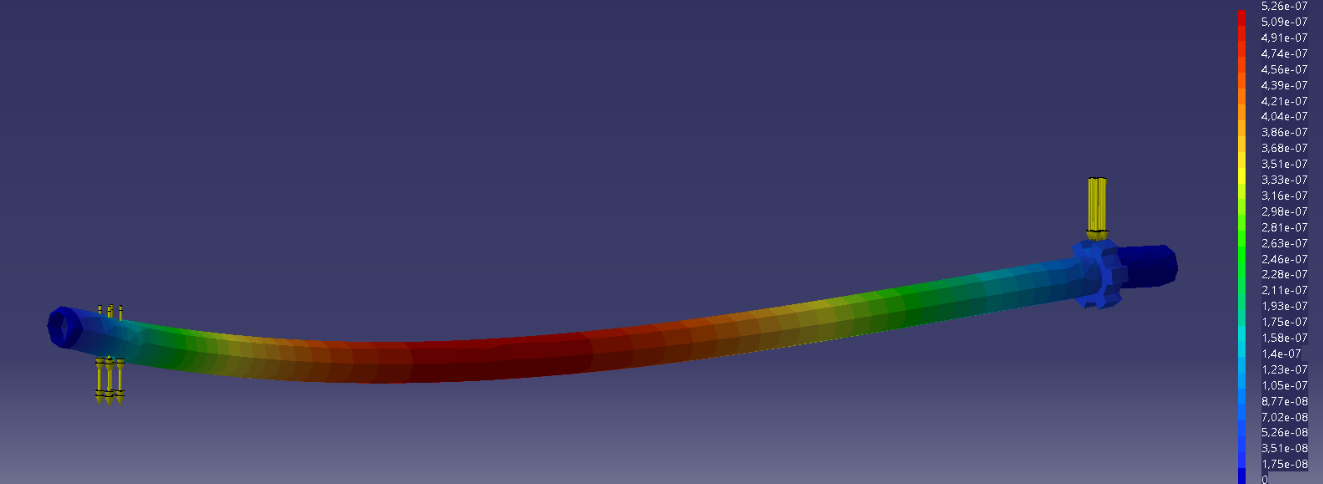

We sized the shaft using the worst-case bending moment from launch (25.26 Nm) and ECSS safety factors of 1.25 against fracture and 1.1 against yielding. The final geometry is an 8 mm outer-diameter, 6 mm inner-diameter hollow shaft, which satisfies both strength and mass requirements.

To size the motor, we:

- Computed friction torque from bearing friction and centrifugal forces in the open cover.

- Calculated rotational inertia of the cover and shaft to get the required acceleration torque for a 0–140° motion in 30 s.

- Applied ECSS-recommended safety margins, then selected a motor with 2.5 mNm stall torque, giving a margin of 1.23 over the required 2.03 mNm.

2. Launch-Lock Assembly (LLA)

The LLA prevents any motion of the cover during launch and releases it once the satellite is safely in orbit. The customer required a TiNi Aerospace Frangibolt FC2 as the non-pyrotechnic release device.

Our design uses a titanium fastener bolt with a calibrated circumferential groove acting as a planned fracture section. When the Frangibolt expands, the axial force in the fastener exceeds the allowable load of this necked section and the bolt shears in a controlled way. The groove diameter was chosen so that:

- It always breaks under the maximum actuator force of 3781 N, and

- It still has a safety margin of 1.99 against the maximum structural load of 1900 N transmitted through the locked cover.

To avoid jamming due to manufacturing tolerances, the bolt is guided by three eccentric pins that allow small lateral adjustments. Two “kick-springs” help the cover overcome the motor holding torque immediately after release, while containment housings and a damper ensure that no fragments are released into space and impact shocks are reduced.

III. Results & Evaluation – Feasibility & Effectiveness

We evaluated the design through analytical calculations, ECSS-based safety checks, and FEM simulations of critical components such as the shaft and eye-brackets.

- Structural safety: All metallic parts meet or exceed ECSS factors of safety (≥1.25 for ultimate, ≥1.1 for yield). Shaft stresses remain within allowable limits, and key fasteners and lugs show adequate margins against both fracture and yielding.

- Bearing life & tolerances: PTFE bearings are sized for launch loads and expected actuation cycles (ground testing plus in-orbit operations), with tolerance stacks ensuring proper fits over the operating temperature range.

- Kinematics & timing: The motor-spring system achieves the required 0°–140° motion within 30 s, with sufficient torque margin to overcome friction and worst-case cold startup conditions.

- Safety & reliability: Dual containment for the fractured bolt pieces, non-pyrotechnic actuation, and passive damping reduce contamination and shock loads on the telescope structure.

Overall, the mechanism meets the functional and structural requirements of the course brief and would be a feasible candidate for a small scientific satellite, subject to further qualification testing.

IV. My Role & Contributions

The project was completed in a four-person team; I contributed a substantial share of the workload in the draft design and analysis phases. My main responsibilities were:

- Shaft & bearing design: Derived launch load cases, computed reaction forces and bending moments, and sized the Ti-6Al-4V hollow shaft and PTFE bearings to satisfy ECSS safety margins.

- Motor sizing & actuation concept: Developed the torque budget, selected the phySPACE stepper motor, and defined the motion profile for opening and closing.

- Launch-lock mechanics: Assisted in the sizing of the Frangibolt fastener groove, the kick-spring forces, and the eccentric pin arrangement to manage tolerances.

- Analysis & documentation: Performed hand calculations and FEM checks for critical components and co-authored the “Draft Design” and “Analysis and Verification” chapters of the report.

Through this project I gained hands-on experience with spacecraft mechanism design, ECSS-compliant sizing, and the practical trade-offs between mass, reliability, and manufacturability.